Delving into the world of Six Sigma White Belt answers, this comprehensive guide unravels the secrets of this powerful methodology, empowering you to enhance quality, efficiency, and customer satisfaction within your organization. From defining the core concepts to exploring real-world applications, this in-depth analysis provides a roadmap for success in process improvement.

As we embark on this journey, we’ll uncover the significance of Six Sigma in various industries, demonstrating how its principles can transform operations and drive tangible results. Through engaging examples and practical insights, you’ll gain a deep understanding of the DMAIC process and the statistical tools that empower White Belt practitioners to make data-driven decisions.

Definition and Overview

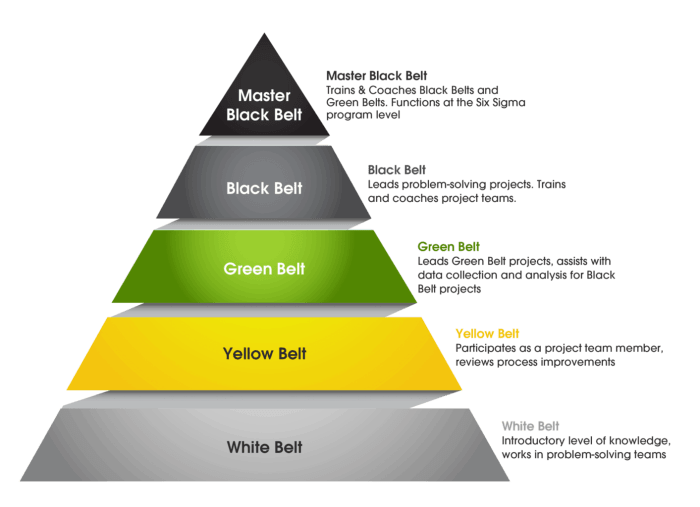

Six Sigma White Belt certification signifies the foundational understanding of the Six Sigma methodology, a data-driven approach to improving processes and reducing defects. It equips individuals with basic tools and techniques for identifying and eliminating waste, enhancing efficiency, and achieving operational excellence.

Significance of Six Sigma

Six Sigma methodology has gained widespread recognition across various industries, including manufacturing, healthcare, finance, and service sectors. Its focus on data analysis, process optimization, and continuous improvement has led to significant improvements in quality, productivity, and customer satisfaction.

Applications of White Belt Principles

White Belt principles can be applied in real-world scenarios to address various challenges. For instance, in a manufacturing setting, they can help identify and eliminate defects in production processes, reducing waste and improving product quality. In a healthcare context, White Belt principles can aid in streamlining patient care processes, reducing wait times, and enhancing overall patient experience.

Key Concepts and Tools

Six Sigma White Belt certification lays the foundation for understanding the core principles and methodologies of Six Sigma. It provides a comprehensive overview of the key concepts and tools that enable individuals to contribute to process improvement initiatives within their organizations.

Six Sigma White Belt answers are the key to unlocking a deeper understanding of quality improvement methodologies. To enhance your knowledge, consider exploring the ICC G13 practice test free . This resource offers a comprehensive overview of the ICC G13 certification exam, helping you reinforce your grasp of Six Sigma White Belt concepts and prepare for success.

The DMAIC (Define, Measure, Analyze, Improve, Control) process serves as the framework for Six Sigma projects. Each phase involves specific activities designed to systematically identify, measure, and eliminate variations in processes, leading to improved efficiency and effectiveness.

Statistical Tools and Techniques

Six Sigma White Belt training emphasizes the application of statistical tools and techniques to analyze data and identify areas for improvement. These tools include:

- Descriptive statistics (e.g., mean, median, standard deviation)

- Hypothesis testing

- Regression analysis

- Control charts

- Pareto charts

- Cause-and-effect diagrams (Ishikawa diagrams)

By leveraging these tools, Six Sigma White Belts can objectively evaluate data, uncover patterns, and make data-driven decisions to optimize processes and reduce waste.

Training and Certification

Obtaining Six Sigma White Belt certification opens doors to career advancement and demonstrates your commitment to quality improvement. Here’s how you can get certified and enhance your skills.

Methods of Certification

- Online Courses:Convenient and flexible, with self-paced learning and online assessments.

- In-Person Training:Instructor-led programs offer hands-on experience and interaction with peers.

- Company-Sponsored Programs:Many organizations provide in-house training and certification opportunities.

Typical Content and Structure

White Belt training typically covers:

- Introduction to Six Sigma and DMAIC

- Basic statistical tools and data analysis

- Process improvement methodologies

- Project management fundamentals

Programs often include case studies, simulations, and practical exercises to reinforce learning.

Tips for Preparation

- Review Training Materials:Thoroughly study the provided materials and complete any assignments.

- Practice Case Studies:Solve practice case studies to apply concepts and improve problem-solving skills.

- Join Study Groups:Collaborate with other learners to share knowledge and clarify doubts.

- Utilize Online Resources:Explore online forums, articles, and videos to supplement your learning.

- Take Practice Exams:Simulate the actual exam to identify areas for improvement.

Career Impact and Benefits

Earning a Six Sigma White Belt certification unlocks a multitude of benefits for both individuals and organizations. It demonstrates a commitment to continuous improvement, enhances job performance, and opens doors to career advancement opportunities.

Individual Benefits

- Improved Job Performance:White Belt knowledge empowers individuals with problem-solving techniques and data analysis skills, leading to increased efficiency and effectiveness in their roles.

- Career Advancement:Certification signals a dedication to quality and process improvement, making individuals more competitive in the job market and eligible for promotions.

- Personal Growth:The White Belt journey involves learning new concepts, developing analytical skills, and fostering a growth mindset.

Organizational Benefits

- Enhanced Process Quality:White Belt-trained employees identify and eliminate waste, reduce defects, and improve overall process quality.

- Increased Productivity:Optimized processes lead to faster cycle times, higher output, and reduced costs.

- Improved Customer Satisfaction:By focusing on customer needs and reducing errors, White Belt practices enhance customer satisfaction and loyalty.

Real-Life Examples

- A White Belt-certified employee at a manufacturing plant implemented a process improvement that reduced production defects by 20%, resulting in significant cost savings and increased customer satisfaction.

- In the healthcare industry, a White Belt-trained nurse redesigned a patient registration process, reducing wait times by 30% and improving patient experience.

- A White Belt-certified engineer in the automotive sector identified a design flaw that led to a recall, preventing potential safety hazards and reputational damage for the company.

Examples and Case Studies

Six Sigma White Belt principles and tools have been successfully applied in various industries, leading to significant improvements in quality, efficiency, and customer satisfaction. Here are a few case studies that demonstrate the impact of White Belt projects:

Case Study 1

A manufacturing company implemented a White Belt project to reduce defects in its production process. By using Six Sigma tools such as process mapping and statistical analysis, the team identified the root causes of defects and developed solutions to eliminate them.

As a result, the defect rate was reduced by 30%, leading to significant cost savings and improved product quality.

Case Study 2

A healthcare provider used Six Sigma White Belt principles to improve patient satisfaction in its emergency department. The team analyzed patient feedback and identified areas for improvement. By implementing process changes and training staff on patient-centered care, the department significantly reduced patient wait times and improved patient satisfaction scores.

Case Study 3, Six sigma white belt answers

A financial services company applied White Belt tools to streamline its account opening process. The team used process mapping and DMAIC (Define, Measure, Analyze, Improve, Control) methodology to identify and eliminate bottlenecks. The result was a 25% reduction in account opening time, improving customer satisfaction and operational efficiency.

Answers to Common Questions: Six Sigma White Belt Answers

What is Six Sigma White Belt certification?

Six Sigma White Belt certification is an entry-level credential that provides a foundational understanding of Six Sigma principles and methodologies, equipping individuals to participate in process improvement projects.

How can I obtain Six Sigma White Belt certification?

Various training providers offer Six Sigma White Belt certification programs, which typically involve online or in-person training followed by an exam.

What are the benefits of Six Sigma White Belt certification?

Six Sigma White Belt certification demonstrates your commitment to quality improvement, enhances your problem-solving skills, and opens doors to career advancement opportunities.